Loop is a desktop filament maker designed to recycle leftover plastic and failed 3D prints into reusable, high-quality filament. It offers a quick, efficient, and sustainable solution for 3D printing enthusiasts and professionals, reducing waste and costs while promoting environmental responsibility. The device is durable, precise, and easy to use, making it a practical tool for creating custom filament at home.

At the core of Loop’s functionality is its ability to transform discarded plastic and failed 3D prints into reusable filament. This capability not only reduces the environmental footprint of 3D printing but also provides a tangible way to repurpose materials that would otherwise contribute to waste. The device is compatible with widely used thermoplastics such as PLA and ABS, making sure broad applicability across various 3D printers. By reducing the reliance on purchasing new filament rolls, Loop enables users to adopt a more sustainable and cost-effective approach to their projects.

Loop 3D Filament Maker

TL;DR Key Takeaways :

- The Loop desktop filament maker recycles plastic waste and failed 3D prints into reusable, high-quality filament, promoting sustainability in 3D printing.

- It offers fast and efficient filament production in under 30 minutes with minimal user input, making it ideal for both professionals and hobbyists.

- Precision engineering ensures consistent filament quality with a diameter accuracy of 0.01 mm, critical for reliable 3D printing results.

- Customizable filament options (diameters from 0.5 mm to 3.5 mm) and compatibility with popular thermoplastics like PLA and ABS enhance its versatility.

- Durable construction, quiet operation, and a user-friendly design make Loop a cost-effective, eco-conscious, and accessible solution for all skill levels.

- Launching Q2 2025 reserve yours now and get an exclusive discount

Key benefits of Loop’s recycling feature include:

- Minimizing plastic waste by repurposing discarded materials.

- Reducing the environmental impact of 3D printing activities.

- Providing compatibility with popular thermoplastics for versatile use.

Streamlined Efficiency: Faster and Simpler Filament Production

Loop is engineered for efficiency, producing filament in under 30 minutes with minimal user intervention. Its automated extrusion and spooling system simplifies the process, allowing users to focus on their creative designs rather than the technical aspects of filament production. This streamlined functionality makes it an appealing choice for professionals working under tight deadlines and hobbyists seeking a hassle-free recycling experience.

The device’s efficiency is particularly advantageous for:

- Reducing the time required to produce filament.

- Allowing users to focus on design and innovation.

- Providing a convenient solution for both beginners and experts.

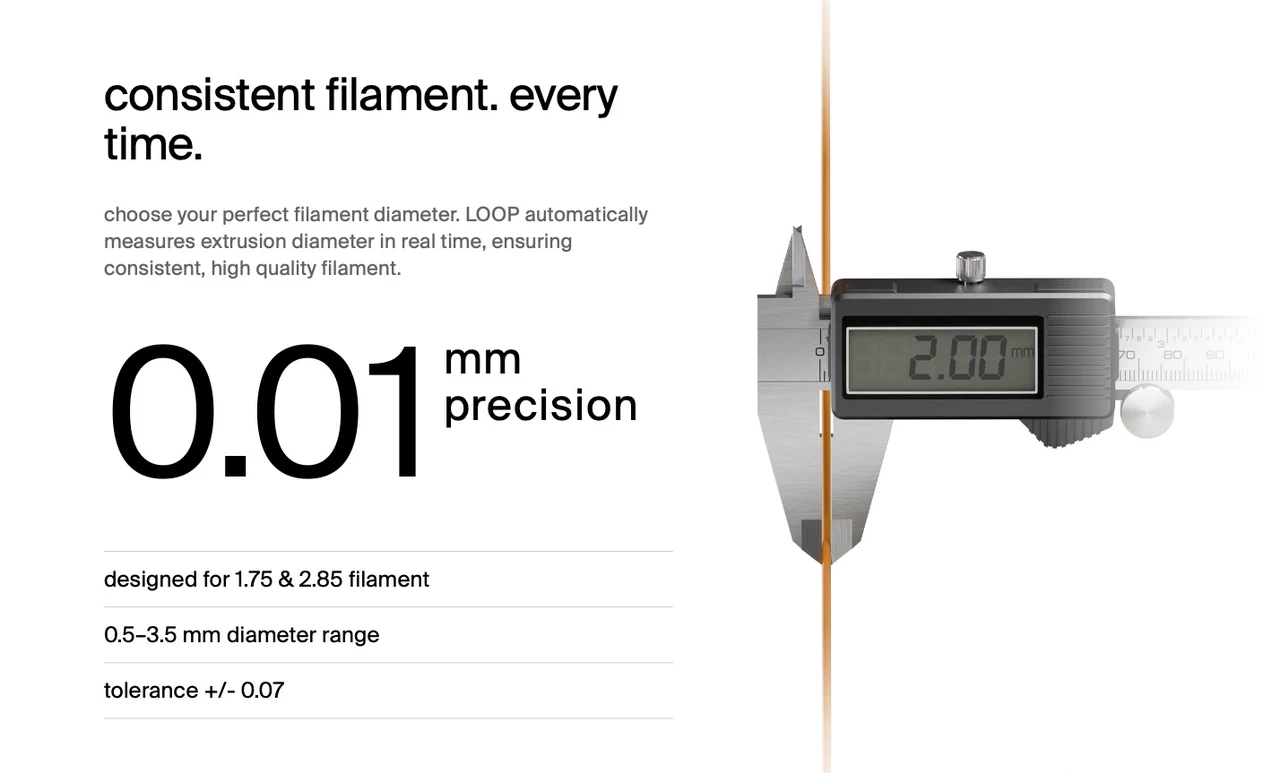

Precision Engineering: Making sure Consistent Filament Quality

One of Loop’s standout features is its precision engineering, which ensures consistent filament quality. The device achieves a diameter accuracy of 0.01 mm through real-time measurement technology, a critical factor for reliable 3D printing results. This level of precision is essential for producing intricate prototypes, functional components, and other complex applications.

By delivering consistent filament quality, Loop supports:

- Improved reliability in 3D printing outcomes.

- Enhanced performance for detailed and complex designs.

- Reduced material waste due to fewer printing errors.

Customization Options: Tailored Filament for Diverse Needs

Loop offers flexibility in filament production, supporting both 1.75 mm and 2.85 mm filament diameters to accommodate a wide range of 3D printers. Additionally, users can customize the filament diameter within a range of 0.5 mm to 3.5 mm, with a tolerance of +/- 0.07 mm. This adaptability allows users to tailor filament specifications to meet the unique requirements of their projects, making it a versatile tool for professionals and enthusiasts alike.

Durable Construction: Built for Long-Term Use

Constructed from high-quality materials such as aluminum, stainless steel, and wear-resistant blades, Loop is designed for durability and longevity. Its robust construction ensures reliable performance over time, reducing the need for frequent repairs or replacements. This durability aligns with the device’s sustainability goals by minimizing waste associated with short-lived products.

Quiet Operation: Enhancing the Workspace Environment

Noise is a common concern in 3D printing, particularly in shared or home environments. Loop addresses this issue with an insulated sound shield that significantly reduces operational noise. This feature makes it suitable for use in offices, studios, and homes, creating a quieter and more comfortable workspace without compromising performance.

Environmental Impact: Supporting a Greener Future

By converting plastic waste into reusable filament, Loop contributes to a more sustainable 3D printing ecosystem. This aligns with global efforts to combat plastic pollution and encourages responsible consumption within the 3D printing community. The device’s eco-friendly approach positions it as a tool that not only benefits individual users but also supports broader environmental objectives.

Cost Efficiency: Reducing Expenses for Users

In addition to its environmental benefits, Loop offers significant cost savings. By eliminating the need to purchase new filament rolls, frequent users can reduce their expenses over time. The ability to produce custom filament at home further enhances its value, making it a cost-effective solution for professionals and hobbyists alike.

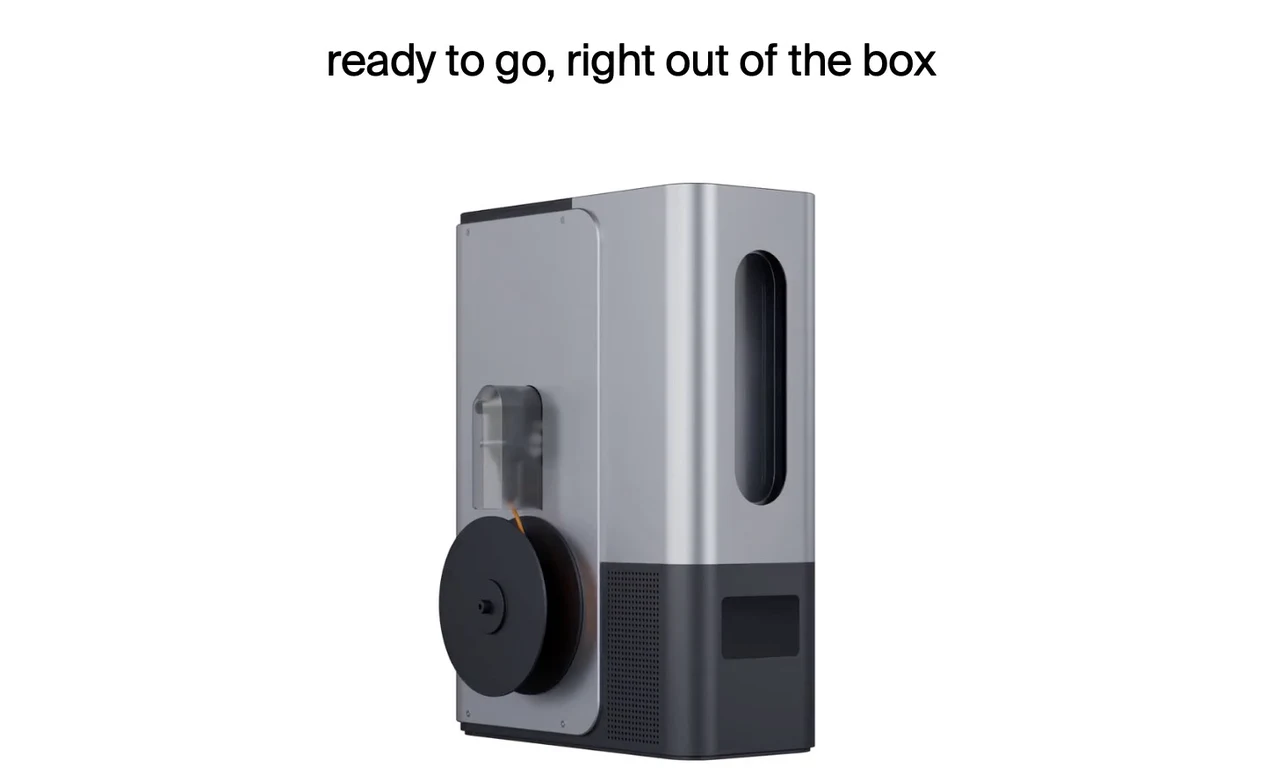

User-Friendly Design: Accessible and Intuitive

Loop’s intuitive interface and automated spooling system make it accessible to users of all skill levels. The device is ready to operate straight out of the box, requiring no complex setup or technical expertise. This user-friendly design ensures that both beginners and experienced users can take full advantage of its advanced features, making sustainable filament production more attainable.

Key Features of the Loop Desktop Filament Maker

- Recycles plastic waste and failed prints into reusable filament.

- Produces filament in under 30 minutes with minimal user input.

- Delivers consistent filament quality with a diameter accuracy of 0.01 mm.

- Supports customizable filament diameters from 0.5 mm to 3.5 mm.

- Constructed from durable materials for long-term use.

- Operates quietly, suitable for home and office environments.

- Reduces costs by eliminating the need for new filament rolls.

- Features an intuitive design for users of all experience levels.

The Loop desktop filament maker offers a practical and sustainable solution for the 3D printing community. By addressing key challenges such as waste reduction, cost efficiency, and environmental sustainability, it provides users with a reliable and versatile tool for creating high-quality filament. Its combination of advanced technology, user-friendly design, and eco-conscious features positions it as a valuable addition to the evolving landscape of 3D printing.

Filed Under: Gadgets News, Hardware

Latest Geeky Gadgets Deals

Disclosure: Some of our articles include affiliate links. If you buy something through one of these links, Geeky Gadgets may earn an affiliate commission. Learn about our Disclosure Policy.